Epoxy iron cloud middle coating Waterborne epoxy cloud iron intermediate paint environmentally friendly

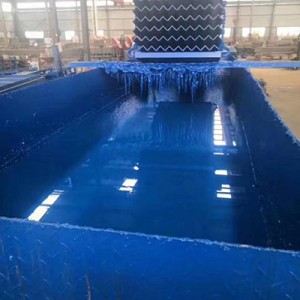

Application

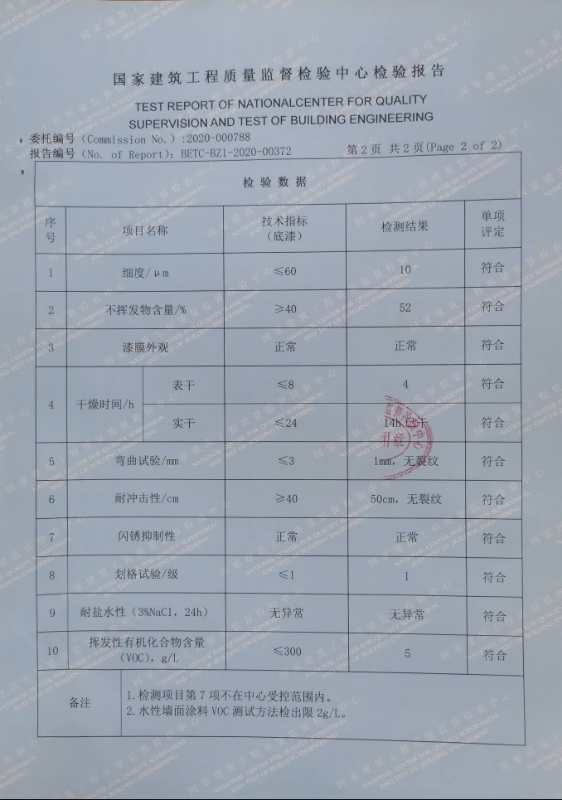

Main features 1. Very low VOC, with water as diluent, environmentally friendly.

2.Non-flammable and explosive, can be transported as non-dangerous goods, safe and reliable.

3. Excellent adhesion to the primer, dense anti-penetration paint film, strong sealing performance.

4. Excellent physical and mechanical properties of paint film after drying, can be matched with all kinds of topcoats.

Technical parameters Color Gray

Solid content 60±2%

Shine No light

Drying time (25℃℃) is shown in 1 hour.

24 hours of operation

Fully cured in 7 days

Drying (70-80°C) 2 hours solid drying

Varnish hardness

Paint film adhesion level 1

Paint film flexibility 2mm

Paint film impact resistance 50cm.kg.

Theoretical coating rate 8m'/kg (dry film 40μm)

Quick Details

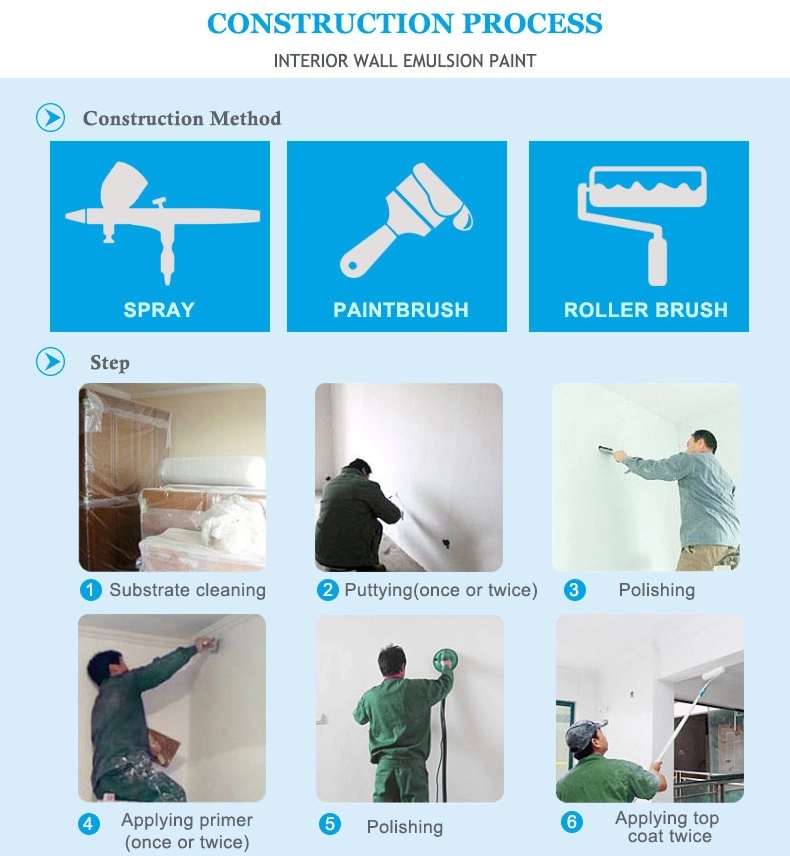

Construction method Proportion component A: component B = 9:1

Construction method Air/airless spraying

Thinner Clean water

Dilution 5-15%

Nozzle diameter 1.5-2.5mm

Spraying pressure 0.4-0.6Mpa

Service period 3h (at 20°C)

Painting kit Select the kit system according to the requirement. This product is not recommended to be used alone, but can be used with most of our water-based or solvent-based primers and topcoats.

Packing specification: component A: 18kg/barrel, component B: 2kg/barrel.

The data of construction environment is the same as that of "H602 waterborne epoxy primer", please refer to it.

Waterborne epoxy primer

Product Description This product is made of water-based ring carrier nozzle, water-based additives, environmentally friendly antirust filler, water-based epoxy coating agent, deionized water, etc. by special process, A, B two-component independent packaging.

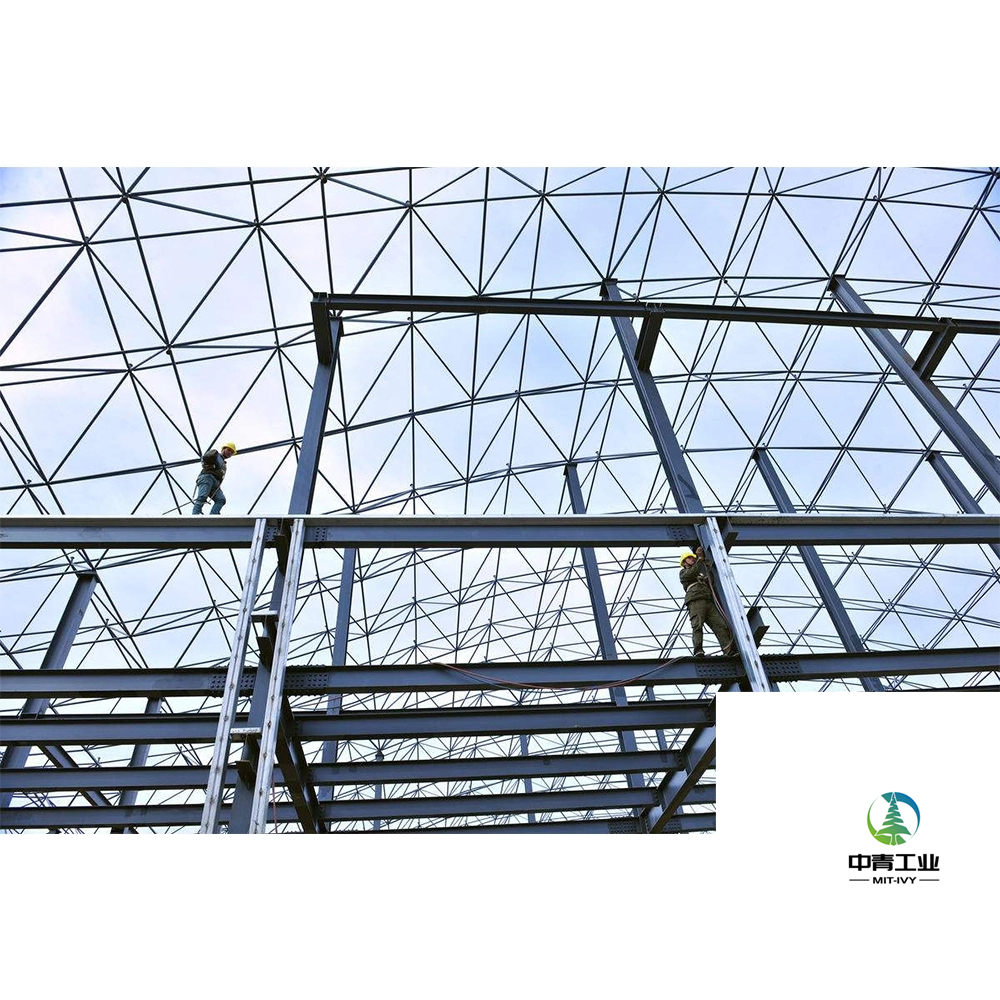

Recommended use: Anti-corrosion coating on the surface of underground pipes, construction machinery, electric power facilities, mining equipment, chemical equipment, construction steel and other steel. Surface coating of automobile parts such as axles.

3. Anti-seepage coating on cement, metal products, aluminum products, FRP surface coating.

Main characteristics 1. Extremely low VOC, diluted with water, environmentally friendly products.

2. Each component is non-flammable and non-explosive, can be transported according to non-dangerous chemicals.

3. Excellent physical and mechanical properties, excellent water resistance, alkali resistance.

4: Excellent metal corrosion resistance.

5: Excellent adhesion to various substrates, widely used.

Technical parameters Color Various colors

Solids 55±3%

Glossy No light

Drying time (25'°C) at 1 hour

Actual 24 hours

dryer

Film hardness (70-80℃) Completely cured 7 days.

2 hours of hands-on work

Paint film adhesion H

Steel: Surface spraying and other methods to achieve Sa2.5 grade, with medium surface roughness and stability.

Aluminum: can be mechanically polished with 120# second paper.

This product can be used for other substrates, please contact our technical service personnel for details.

Level 1

Paint film flexibility

Paint film impact resistance

Salt fog resistance 2mm

50cm. kg

Theoretical coating rate 300h

8e1/kg (40μm dry film)

Construction method Proportioning

Construction method Component A:Component B=2:1

Air spray/airless spray

thinner

Dilution amount Clean water

5-15% of the total

Nozzle size

Spraying pressure 1.5-2.5mm

Applicable period 0.4-0.6Mpa

3h (at 20°C)

Surface treatment Before construction, the surface of the coated material should be treated without oil, rust and dust.